digital outlook

Reshape'15 | Wearable Technology Competition

Project Description

Project Detail

multi-material 3D printed eyewear

Inspiration

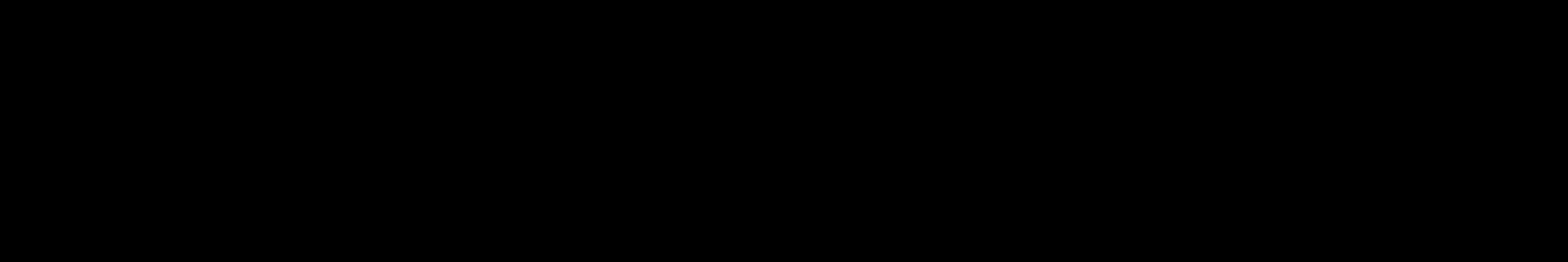

In the age of digitalization, when the human psychic, social and physical space is infiltrated by non-human, design is no longer a controllable creation of one craftsman. It emerges from cooperation between humans and nonhumans. In this period, biology affects the technology and techniques based on Evolutionary Algorithms or Developmental Biology are exploited in design processes. At the same time the natural cognition possibilities and human biology might by enhanced by the technology. The boundary between natural and artificial blurs. The technology becomes natural and native. The presented eyewear explores the boundaries of technology at every stage of their creation trying to become the natural extension of human face.

Stage 1.Data Collection

Data for the design is collected from the precise 3D scans. The unique face morphology is not a limitation any more. Imperfections might became an inspiration and give a new impetus for courageous designs. Data becomes Beauty.

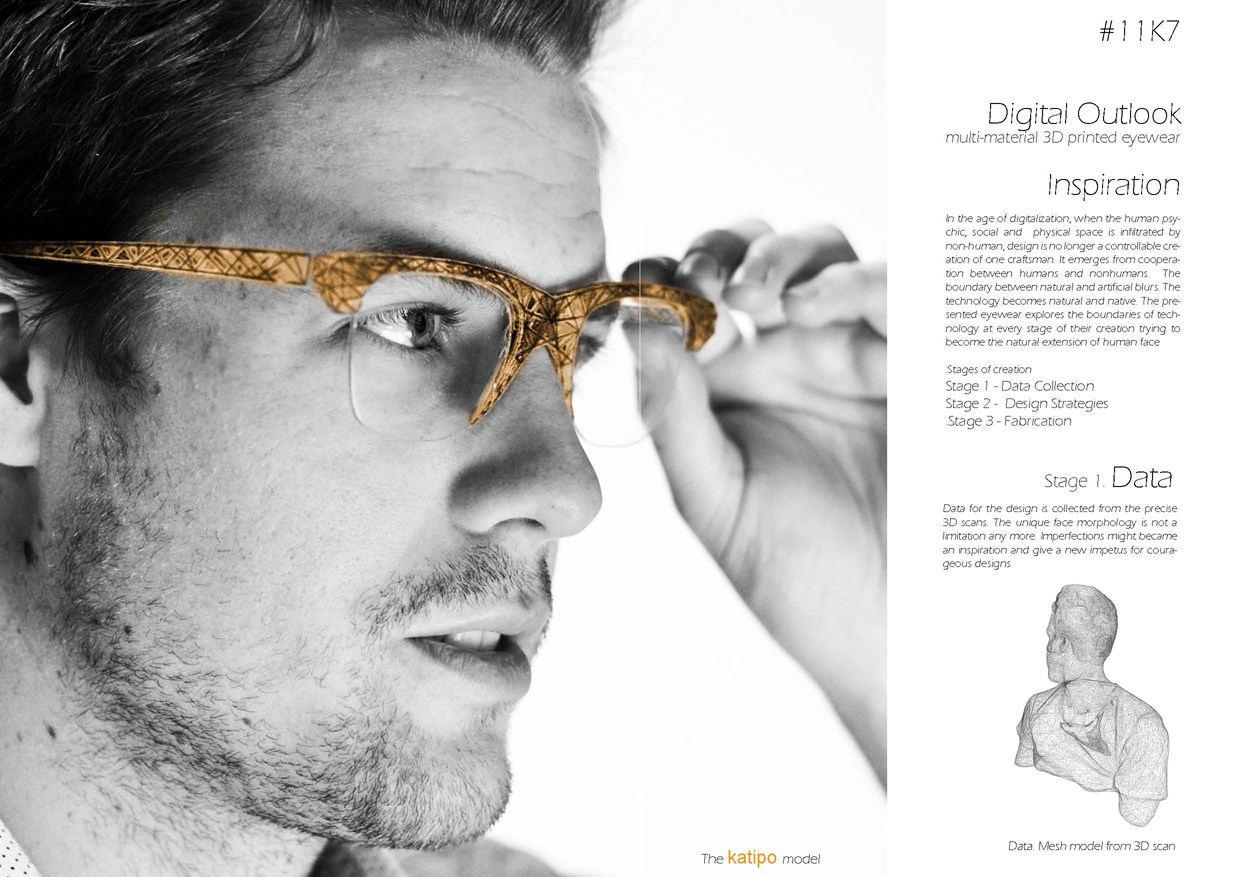

Stage 2. Design Strategy

Technology enhances the design possibilities. Both presented models in different ways explore the potential of computational design.

The first model Katipo(spider) is a light-weight frame, where the initial dense structure is optimized with usage of Bi-directional Evolutionary Optimization (BESO). The BESO algorithm has a wide application in the areas, which require lightweight, low-cost and high performance structures such as biomedical, aero-space and mechanical engineering. The not utilized material is in the iterative way removed from the initial structure resulting in the pure form.

The second model Haptic (touch) is the model with the rubber inclusions in form of balls. The size and density of the inclusions depend on the distance to the face. This simple rule leads to frame design where every place with skin contact is covered with soft rubber.

Stage 3. Fabrication

Project pushes the boundaries of contemporary manufacturing technology by designing the anisotropy. Combining two materials results in the game of soft and hard, black and clear. This contrast is not only an artistic aspect but also a practical approach to merge the material properties. The presented models were printed on the Connex Multi-Material 3D Printer with usage of:

- Transparent material (VeroClear-RGD810) – a rigid, nearly colorless material featuring proven dimensional stability for general purpose, fine-detail model building and visual simulation of transparent thermoplastics such as PMMA.

- Rubber-like black (TangoBlack FLX973) of elastomer characteristics including Shore scale A hardness, elongation at break, tear resistance and tensile strength.

The combination of two materials with radically different physical properties enabled the creation of flexible durable, light-weight, perfectly fitting frames. Digital Outlook eyewear is not an accessory any more, but an extension of face.

TEAM

Judyta Cichocka

Zach Challies

Boutros Bou-Nahara

Heather Akers