Robotic surface manipulation

Reshape'14 | DIGITAL CRAFT COMPETITION

Project Description

Project Detail

Variable Surface Ceramic Tiles & Robotic Roller Tool Design

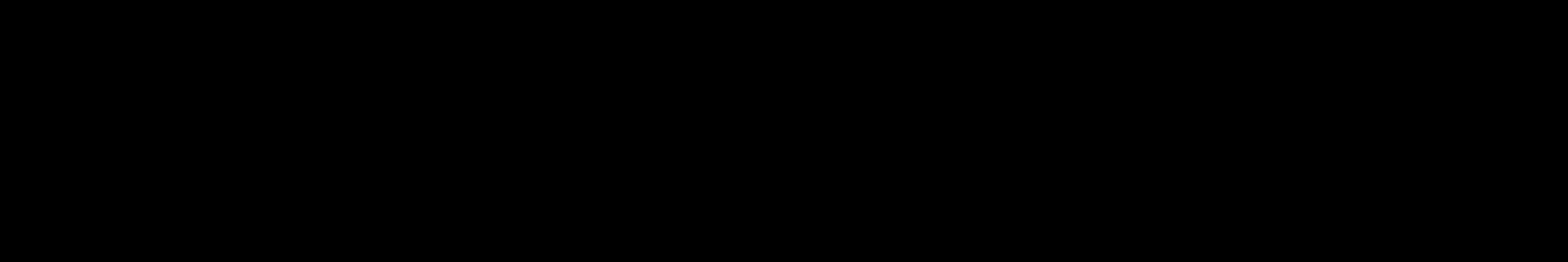

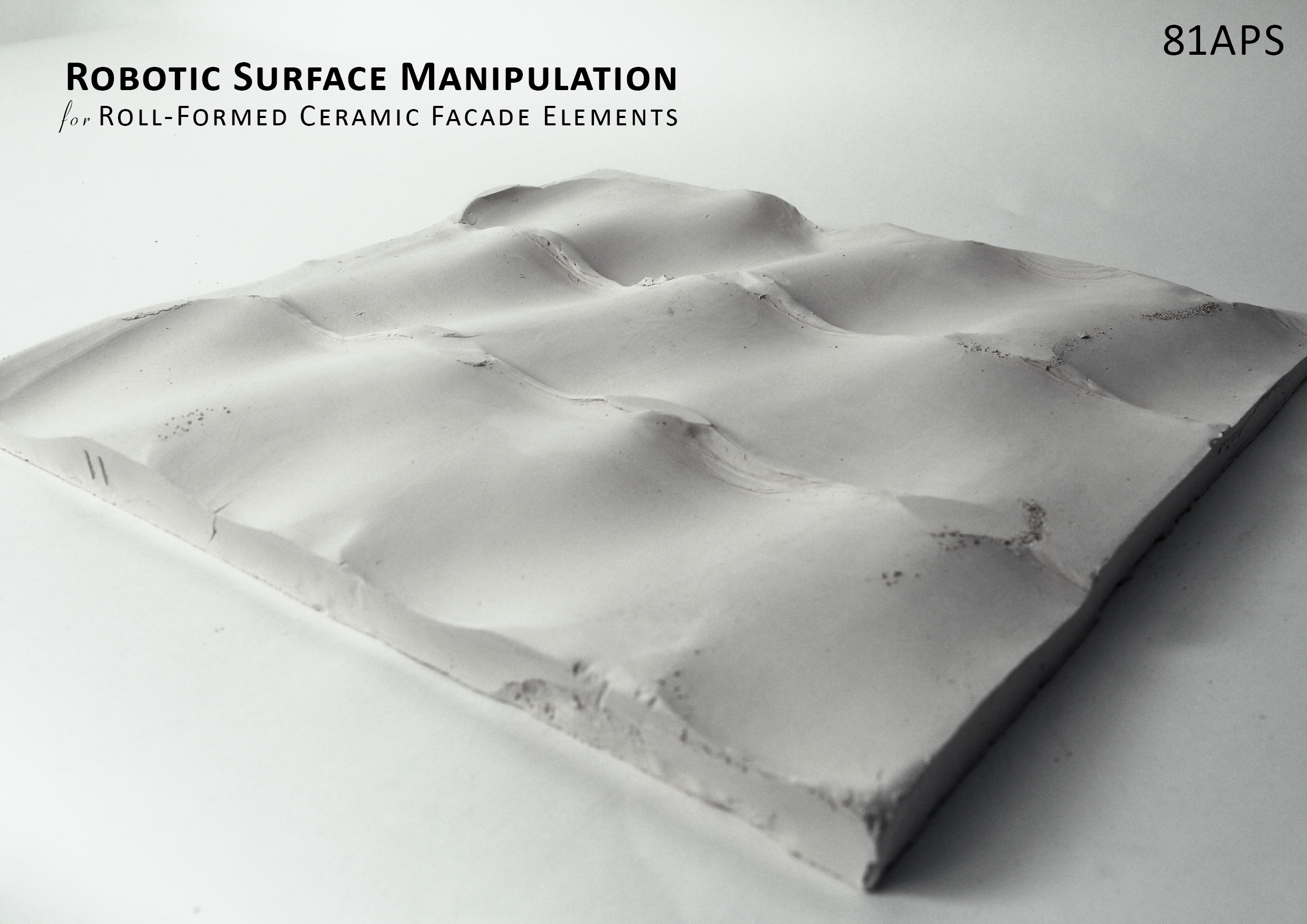

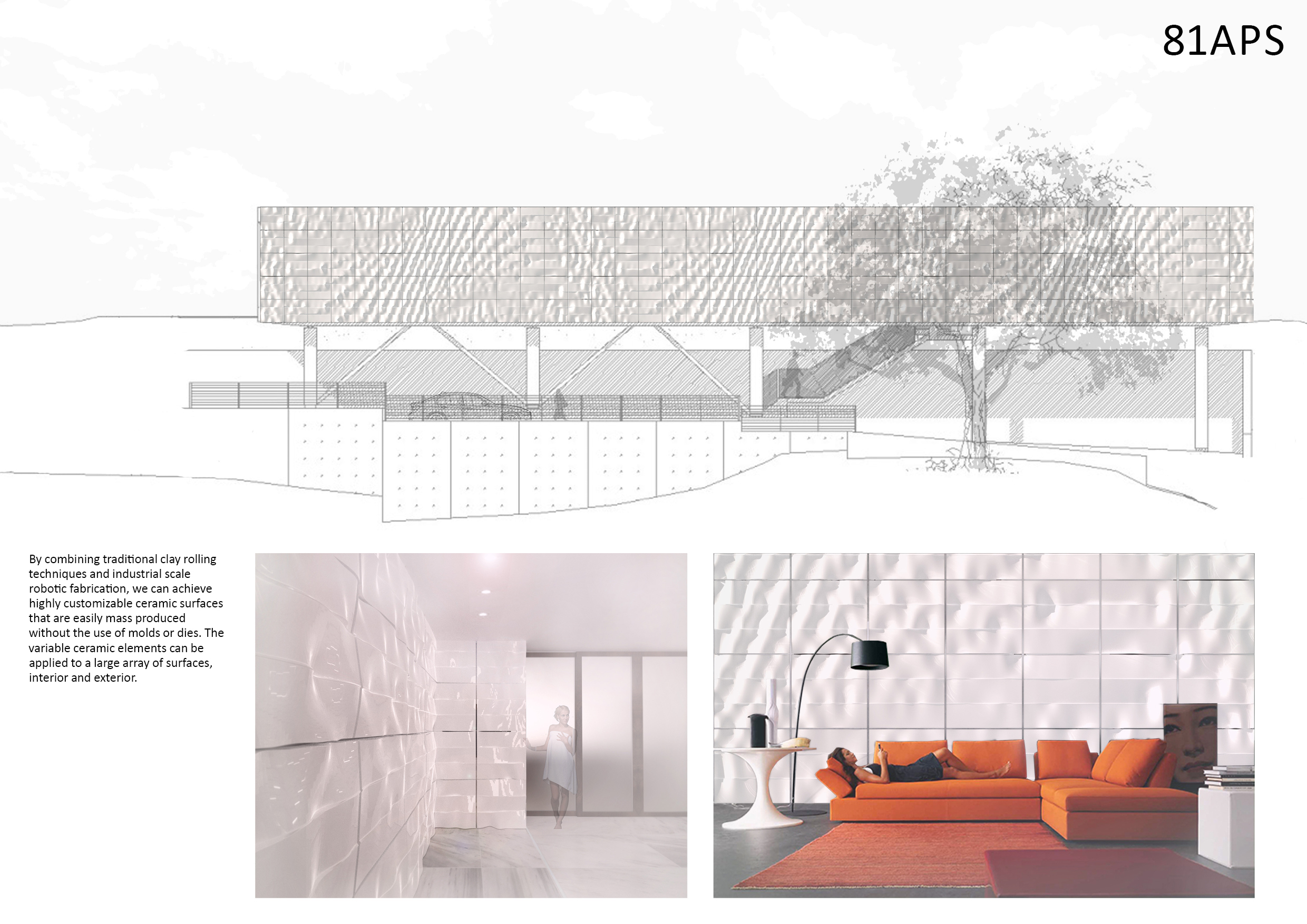

By combining traditional clay rolling techniques and industrial scale robotic fabrication, we can achieve highly customizable ceramic surfaces that are easily mass produced without the use of molds or dies. The variable ceramic elements can be applied to a large array of surfaces, interior and exterior. A combination of traditional clay rolling techniques and industrial scale robotic fabrication is used to develop a highly-customizable ceramic tile production system. The project focuses on designing a new robotically controlled tool that interfaces between the clay and the robotic arm, developing an interactive digital interface for custom design facade systems, and inserting this new system into a high-volume industrial linear extrusion production process. An ABB IRB 4400 robot with the new Robotic Roller tool attached simulates a computer numerically controlled (CNC) mechanism that would be used in the industrial process. A variable surface pattern is designed using Rhino and Grasshopper and then executed by translating this design into a scripted robotic process with HAL and RobotStudio. This produces a sample ceramic façade system that is infinitely variable with a stone white earthenware clay medium. This Robotic Roller method is directly applicable to the current tile production industry. As a process, the variable roller too, can be incorporated into existing tile production lines to develop infinitely customizable tile surfaces without the need to produce molds or other support materials that consume time and resources. Along with an increase in demand for customization, the ceramic industry is turning to innovative fabrication strategies in order to produce highly customizable products. Methods such as linear extrusion, dry press, and wet press are currently used to achieve some degree of customization. However, these methods have limitations when applied to high-volume production processes. Linear extrusion, the leading method for high-volume production, is constrained by the size and shape of the die and the single axis of the extruder. Though dies can be formed in a variety of ways, each unit takes on the form of a single die and cannot achieve any further variation. Dry press and wet press processes allow for larger variability within the shape of a single unit when compared to extrusion. Variability here is dependent on the form of a mold instead of a die. Due to the high cost of creating and installing each mold, few variations are used in high-volume production. By combining traditional clay rolling techniques and industrial scale robotic fabrication, we can achieve highly customizable ceramic surfaces that are easily mass produced without the use of molds or dies. In order to explore what opportunities the combination of these two very different methods allows, a custom roller tool attachment for an ABB IRB 4400 robotic arm was designed and fabricated. For proof of concept, a 6-foot by 6-foot full-scale prototype of a ceramic façade system is produced. This Robotic Roller method is directly applicable to the current tile production industry. As a process, the variable roller can be incorporated into existing tile production lines to develop infinitely customizable tile surfaces without the need to produce molds or other support materials that become waste. The Robotic Roller tool creates an entirely new set of possibilities for an existing production process that is fairly standardized. For the purposes of prototyping and tool experimentation, the ABB IRB 4400 robot is used; however, for industrial purposes, a new dedicated machine could provide the range of movements that are possible with the robot and a more robust capability for rolling large quantities of clay than a robotic arm. By incorporating the roller method into an existing tile production line and developing a functional web based client interface, a market for infinitely variable or customizable tiles can be developed with few changes to existing infrastructure. This process also provides a more sustainable method for producing large quantities of customizable tiles because no molds or auxiliary material is needed to form the tile. This process would expand the market for client customized tile products which is currently expanding.

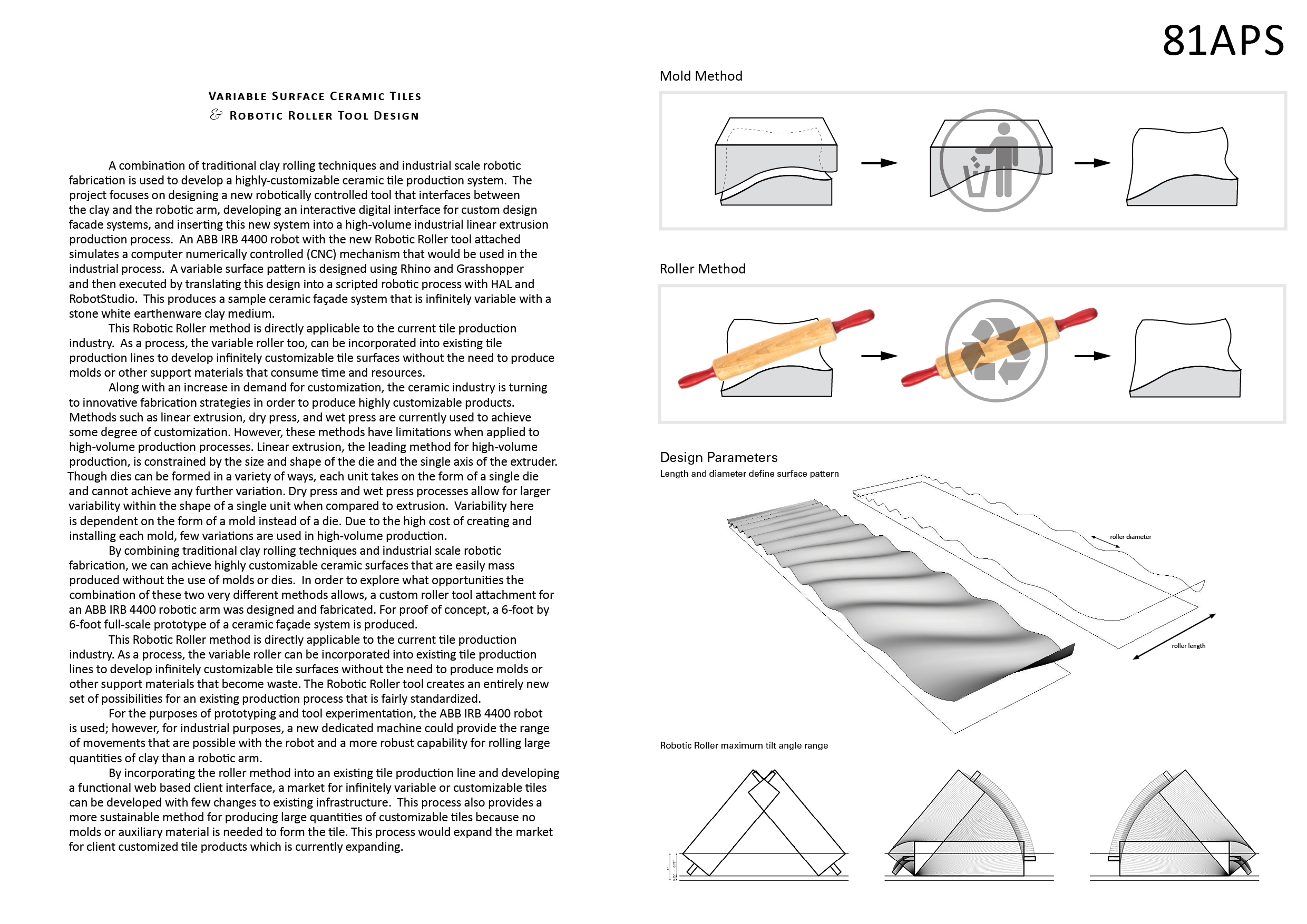

Robotic Roller

The Robotic Roller tool resulted from combining a conventional ceramic roller with an industrial ABB robot. The tool is custom made by attaching the axle of a typical low friction large diameter conveyor roller to a frame made of steel angles and extruded aluminum. The tool has sliding arms that lock in position allowing the length and diameter of the roller to change for different designs. This adjustable feature of the roller attachment allows for an increase in surface design variation as the size, shape and pattern of the roller may be easily changed. The tool can tilt longitudinally to a maximum angle of 45˚ in either direction before causing a collision between the roller axle and the clay.

Surface Design Interface

In order to develop a surface design we propose a website based interface where the client user could develop a custom design by manipulating curves that have given ranges of variation to ensure that the custom designed surface could be achieved with a roller. A client would be guided through a process of tile design first establishing the size of the tiled area and the size of the strips to be rolled. These options then dictate the dimensions of the roller that will be used to produce the design. The client then can manipulate given curves with sliders that control the position and density of the curves. These translations and manipulations are constrained by the tile producer to ensure the viability of the design in the rolling process. Once the client is satisfied with the design, the curves established can then be fed directly into the digital production workflow.

TEAM

Peter Sprowls

Rossitza Kotelova