#2T08

RESHAPE17 | programmable skins

Project Description

Project Detail

There are +300 million of people wearing glasses in Europe. For us, our glasses are a key accessory that needs to represent our style and personality, as our glasses are the first thing other people notice when they look at our face. At the same time, we wear our glasses all day long, so they need to fit us perfectly and be comfortable. While there are a number of glasses brands, it is not easy to find a pair of glasses that fit both our anatomy and style. Bespoke glasses are expensive and inaccessible to the vast majority of people due to cost and experts accessibility.

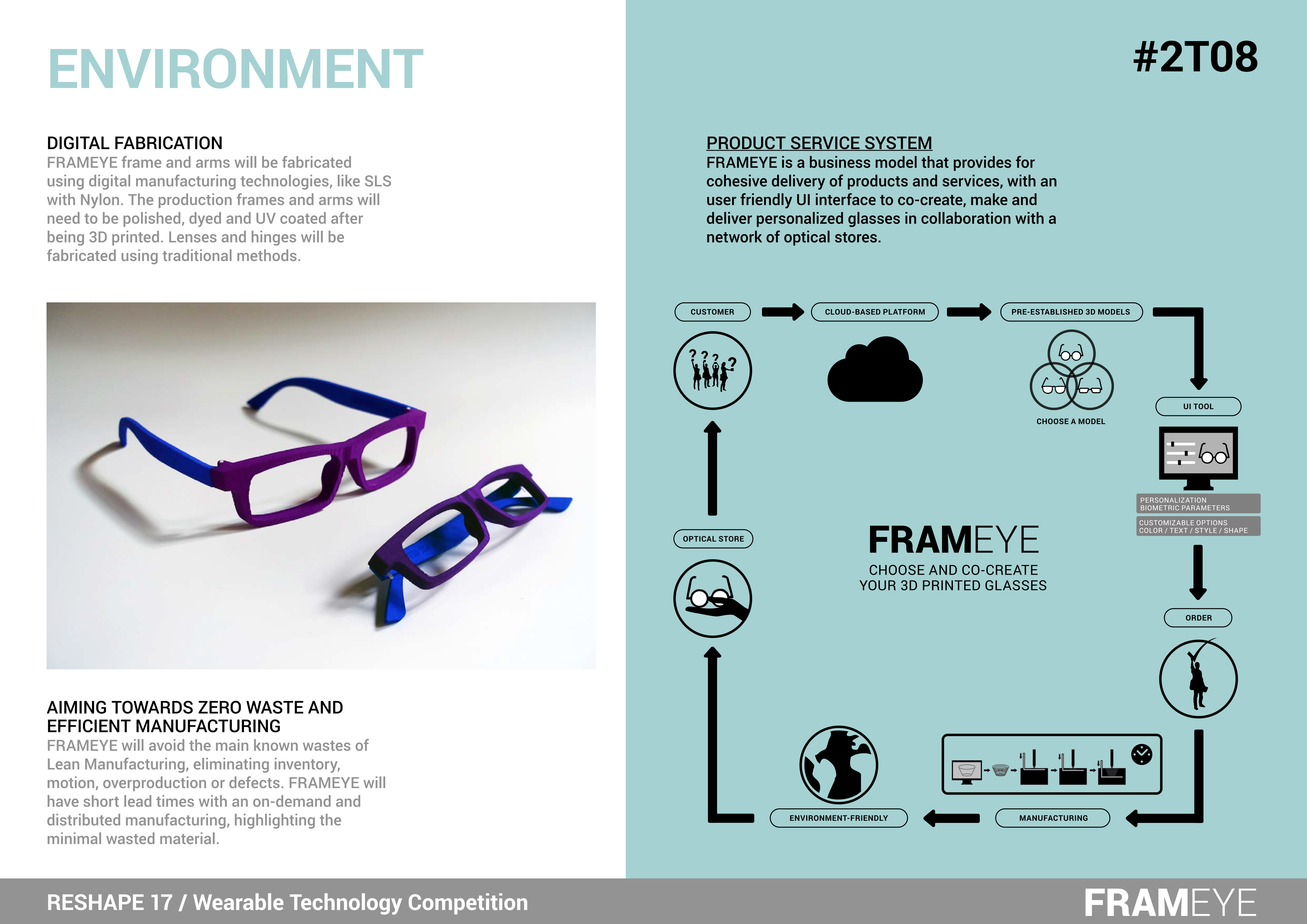

FRAMEYE allows customers to personalize glasses in a way that has not been seen before. Using our specialized software and manufacturing processes, we can make customizable glasses accessible to anyone at very affordable prices.

FRAMEYE’s customers do not have to take any compromise, they get the looks they want and the comfortability that they deserve in the same product. Users will be able to select from different styles and tweak them using a very simple UI to obtain the look that they desire. Additionally, the glasses will be custom fitted to the user, using either 3D scanning or parametric information.

Our baseline models will be conceived by product designers using generative design methodologies. Designs will be transformed into apps that final users will use to personalize and find a perfect fit for their glasses. Every pair of glasses will be unique, and all the information gathered could help designers better understand how products are used and improve future iterations.

Regarding the fabrication process, FRAMEYE frame and arms will be fabricated using digital manufacturing technologies, specifically 3D printing, which produces far less waste than traditional manufacturing technologies. Besides, the materials used are recyclable and some of them are biodegradable. Lenses and hinges will be fabricated using traditional methods; hinges will be off-the-shelf and lenses will be outsourced to opticians. FRAMEYE will outsource each part and then integrate the final product.

Prototypes can be fabricated using 3D printing technologies available in a FabLab or MakerSpace. The main difference between prototypes and final products will be the finishing process applied to the 3D printed parts. The production frames and arms will need to be polished, dyed and coated after being printed.

Our glasses will be sold through both our website and traditional optical stores. This way we can leverage the best of both worlds: online presence using our online store and social networks and a well-established network of optical stores that will be able to assist our customers. First, we will do a small-scale roll-out of our glasses through some key partners, who will help test and improve our processes. We estimate that the first prototypes (software and glasses) will be ready in six months and then we will iterate with our key partners for another six months before we attempt a wider distribution.

FRAMEYE will obtain its revenue from selling glasses online and frames to optical stores. The pricing will be defined considering manufacturing costs and margin per unit. The manufacturing costs are composed of frame manufacturing costs, hinges, lenses, and assembly cost. The margin per unit needs to cover development amortization (software and prototypes), overhead per unit (management, marketing, etc.), and profit per unit. Overall, pricing will be comparable to other similar mainstream brands, in order to make it accessible to most budgets. This means that frame without the glasses will be sold at 120-200€, before taxes. Considering that manufacturing of the frame and the hinge is estimated to be less than 40€, before taxes, and that the optical stores will take a commission, a margin per unit of 50-130€ can be expected.

#2T08

FRAMEYE

| CONCEPT IDEA | 9 |

| PROTOTYPE FABRICABILITY | 9 |

| DISSEMINATION STRATEGY | 9 |

|

|