BEADBOT

Reshape'14 | DIGITAL CRAFT COMPETITION

Project Description

Project Detail

BEADBOT

TOOL DEVELPMENT

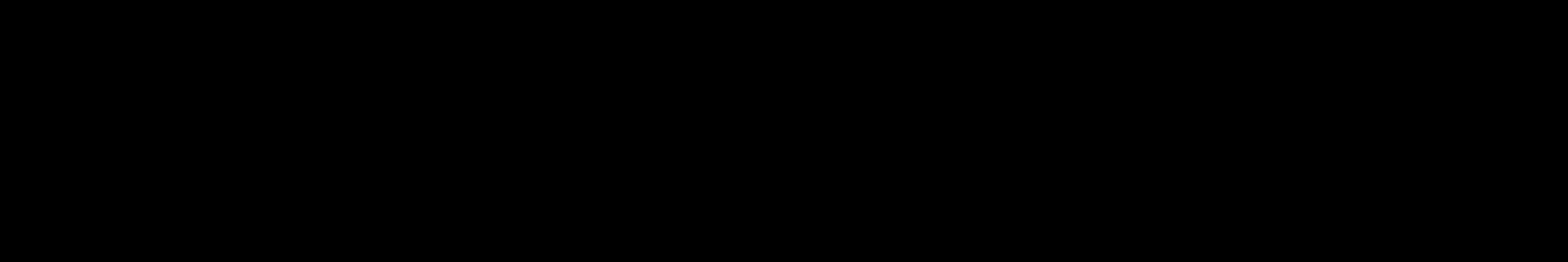

The robotic workflow proposed analyzes the bead rolling process, its potential digital interpretation,and improved fabrication aspects that accompany such a translation. For this process, a robotic tool has been developed integrating multiple variables observed from existing bead rolling machines, while simultaneously allowing for further control a tool Iteration #1:plywood, cabinet doorknob, clamped to table b tool Iteration #2: 2 inch width, 12 inch throat depth, steel and aluminium, machined metal die, attachment to robot through tool changer, spaced out plates allows stiffer engagement of wheels, adjustable bead depth through bolt c tool. teration #3: 3 inch width, 18 inch throat depth, rounded-off metal die, stepper Motor, Arduino microprocessor, added functionality to rotate the wheel combination 90 degrees, slots replaced with lock-in-position Keys d beading mechanism e tool exploded axon.

DIGITAL WORKFLOW

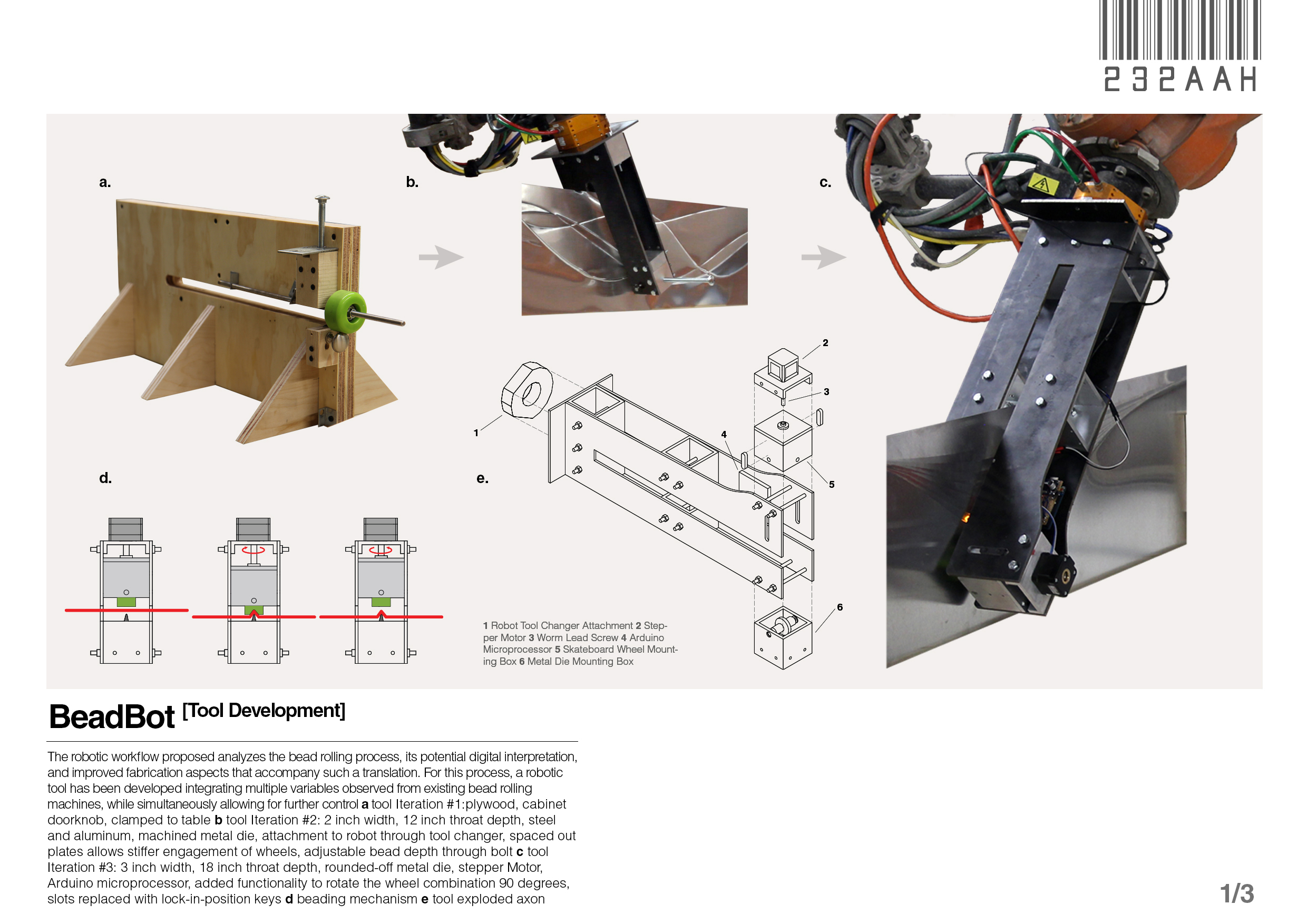

Finite Element Analysis is performed on sheet metal samples given a set of user-defined load parameters and boundary conditions. The outcome is a series of stress vectors acting on the sample. These are hence identified as locations of weakness and where bead corrugations are introduced as means of enhancing the samples structural performance. Vector direction is translated into robotic toolpath while vector magnitude drives the corrugation depth through the tool-mounted microprocessor. The tool allows the beading wheels to be mounted either parallel or perpendicular to the face of the tool. The jig ensures the metal sheet is in place during fabrication while allowing its rotation periodically. a toolpath generation and motor control workflow b line directionality achieved with a 90 degree rotation of the wheel casings c wheel and panel rotation procedures during fabrication.

FABRICATION

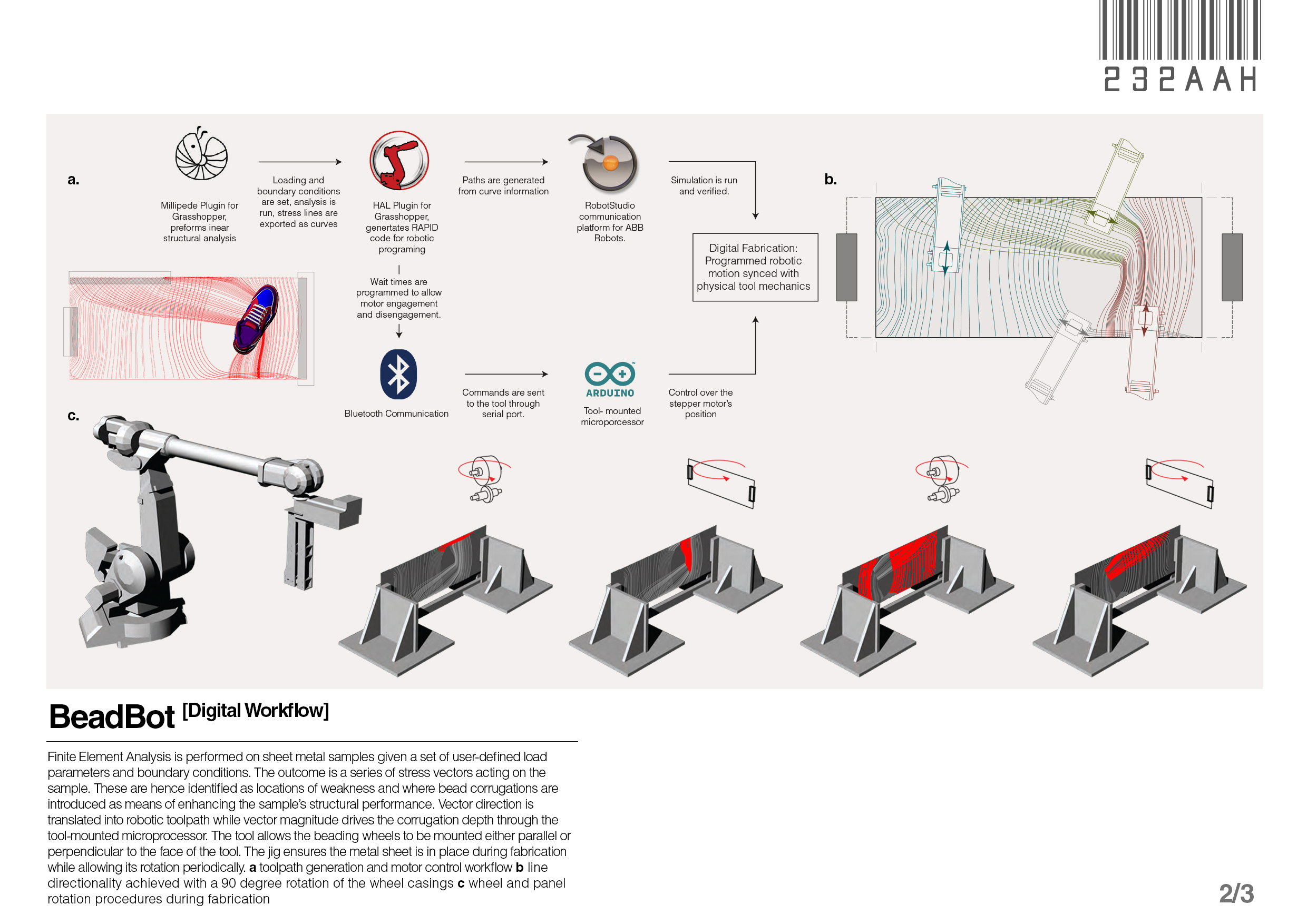

Robotic beading tool development for stressed skin fabrication provokes a wide range of applications from decorative panelling to shelving. This is due to the structural integrity it provides sheet metal and increase in rigidity By approaching material stock as an empty canvas and only treating areas that require additional strengthening, a smoother and simpler approach to structural optimization is achieved. This instigates new formal languages that arise out of pure functional and numerical investigations. By varying the input mode beyond the suggested FE results, any algorithmically generated pattern could be easily formalized in the form of a rapid visual prototype. Robotic bead rolling as an aesthetic impression and its associated play of light across corrugations has proven very provocative, a samples produced by the robotic bead rolling process b fabrication setup.

TEAM

Ahmend Hosny

Amanda Lee

Jared Friedman